An open-source robot project

Goal

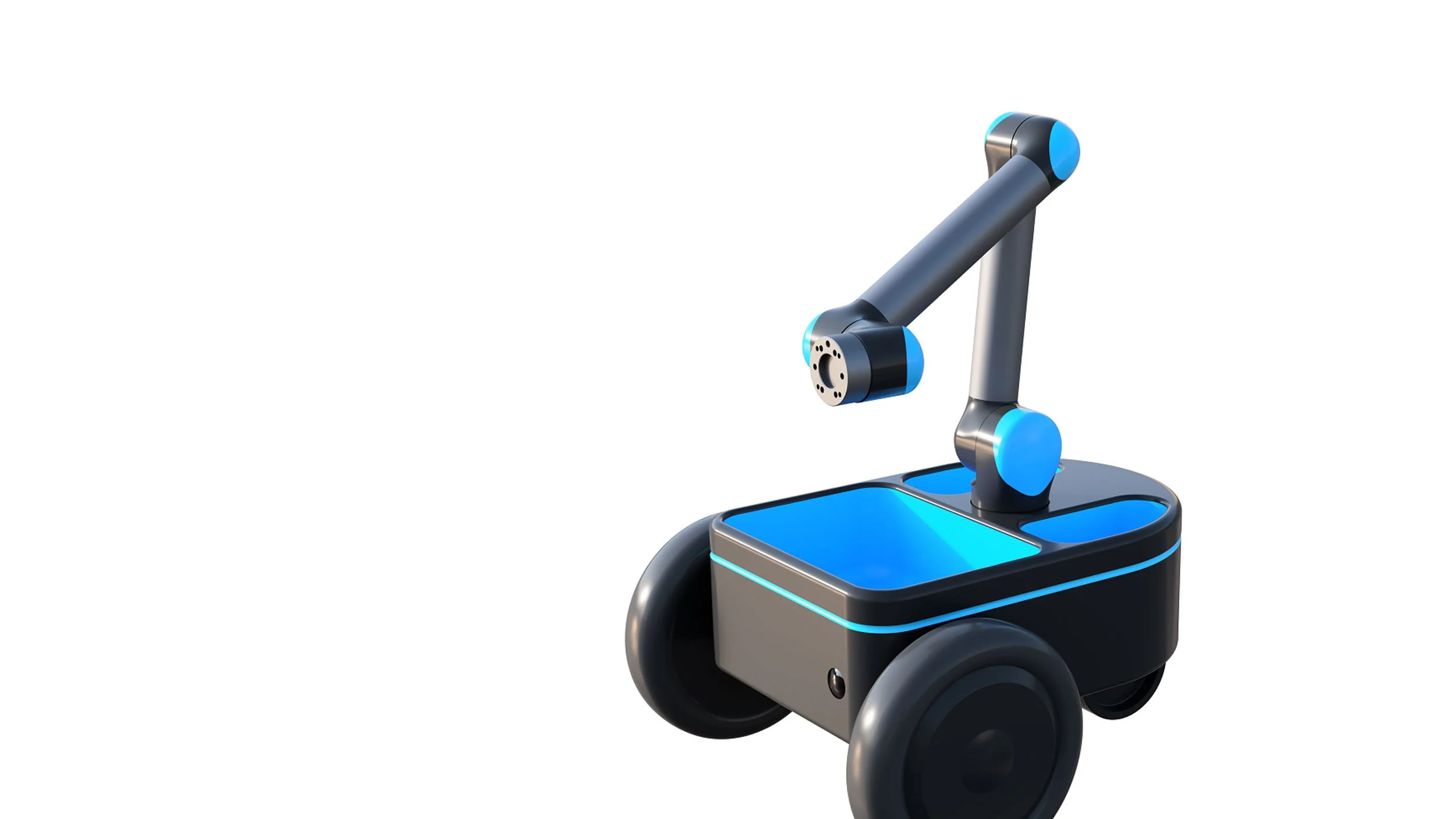

Design an in/outdoor mobile manipulating robot capable of autonomous navigation with the ability to pick up small items. Precision/repeatability should be comparable to industrial robotics. Joint torque sensing to maintain human safety, and used to protect the robot for collisions.

Demonstrate best practices for robot prototyping. Design using obtainable parts and manufacturing tolerances. Design to be assembled by a person of average skill.

Robot project is open source such that robotics engineers can use, modify, and contribute as desired. Extra space is provided in the through bore in the arm to enable running some cables with clean wire routing.

Why

Our group currently consists of 4 highly experienced electrical/mechanical/controls engineers that have been working on robotic hardware for 10's of years.

We've found that robotic hardware requires either significant experience or significant time and iterations to design, tolerance, and control robotic hardware. We've also noticed that there is significant interest in the areas of non-industrial robotics but many groups have difficulty with implementation of the hardware.

Difficulty with hardware slows progress and can lead to misleading results when implementing higher-level control and AI. At the same time, many groups have an interest in design ownership and are not interested in purchasing a platform over which they have little control. With this project, we wish to make our hardware and control experience available at no cost in order to help as much as possible growth in robotics.

Design targets

Music

20 kg device

Two-wheel plus caster base.

5 DOF Manipulating arm with some pulling/lifting force, easily overpowered

Pan, pitch, pitch, pitch, roll

Joint torque sensing

Wrist has offset roll inline with pitch to maintain close grip to wrist pitch

Grip options - spike, actuated spike, vacuum cup, parallel jaw, electrostatic, soft gripper

Strength is 500 g gripper continuous plus 10N peak

Base and wrist cameras

Engineering

Base

Ninebot mini wheels

Kt = .76 Nm/A, 20 A peak

High resolution encoder - ic haus or mps multipole

Ninebot 36V nominal lithium ion battery, 155 Wh

Basket for items

Camera

Computer - Jetson nano

Approximate footprint 600 x 500 WxL

Considering options to do 3 wheel with caster, or 2 wheel self balancing, with movable counterweight. The caster presents difficulty with getting stuck. The 2 wheel requires a counterweight to balance an outstretched arm, and some more challenging dynamics.

Arm

Harmonic Drive® based design

Custom motor for best integration

Integrated module electronics

Integrated torque sensor

Capacitive for easy assembly

Motor encoder

High-resolution MPS on rotor encoder, enables 12bit+3bit

Magnetic encoder to reduce the need for precise gap tolerances and cleanliness

Output absolute encoder

Magnetic encoder to reduce assembly tolerances

Resolution need not be as high - but it’s nice if it is

0.4 x 0.4 m workspace in front of robot

Links 0.3 x 0.3 x 0.1 m upper arm x forearm x grip offset

Grip

Modular

Software

Motor driver software as available here: https://github.com/unhuman-io/freebot-controller

Mid-level software, custom 2 kHz real-time loop. TBD what libraries to use for dynamics. Some initial work has been done using ROS, RBDL, and simulated joystick control in order to investigate camera locations and other kinematics here: https://github.com/unhuman-io/freebot-realtime

Gravity compensation

Cartesian impedance control or

Inverse kinematics with joint torque limits

Higher-level software TBD, currently I’m like at the NVidia jetbot as a starting point.

Get in Touch

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur dignissim neque metus, non porttitor purus cursus non. In hac habitasse platea dictumst.